Explain How to Select Saw Blades for Different Materials

When selecting a saw blade the first and foremost distinction is the material youll be cutting. A good appropriate set is about 8020 with 80 sawdust and 20 air being ejected.

How To Clean A Table Saw Blade 5 Steps With Pictures Instructables

21 Explain how to select saw blades for different materials and how to set the blades for different operations such as cutting externally and internally.

. For example you can use one to cut bolts that are too long or saw through a PVC plastic pipe easily. The type of saw blade to be selected depends on the material that is going to be cut. 21 -Explain how to select saw blades for different materials and how to set the saw blades for different operations such as cutting externally and internallyOn a hacksaw there are many types of blades these blades are different in many ways one of the ways is through the amount of.

Choosing an appropriate set provides a balance between sawdust and air in the space between the body of the saw blade and the material it is cutting. In a plunge cut you rest the base of the saw on the material so that the blade is lined up to saw through the material. In this video David Hall is going to talk and explain the proper way and options to choose a Band Saw Blade when it comes to saw blades.

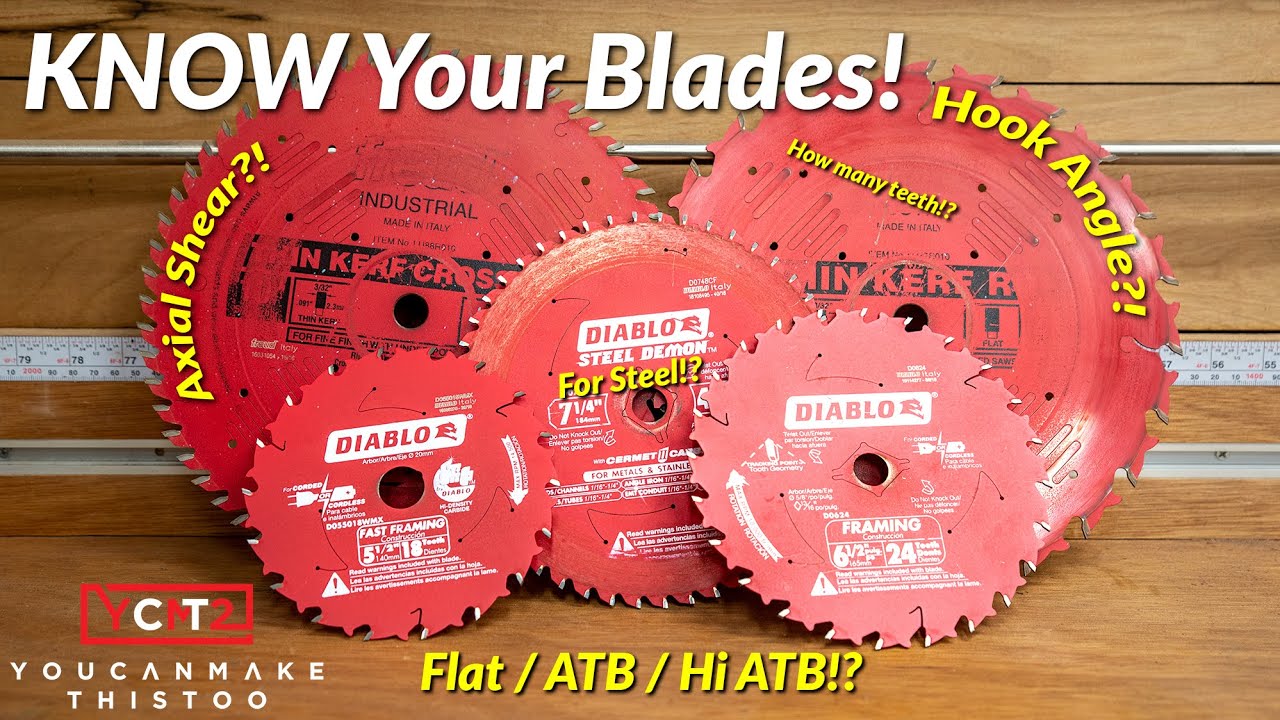

Therefore if you need a versatile saw blade in your workshop for dealing with different types of materials then bad saws are great for you. Saw blades really arent all that complicated. Circular saw blades Made Specifically for plywood.

Saw blades come in a range of cuts depending on the distance between the teeth or teeth per inch. 21 explain how to select saw blades for different. Jewelry tool suppliers offer blades ranging from the finest 80 then 70 60 etc to 0 and larger blades 1 2 and beyond for the.

The sawdust should be warm to the touch not hot or cold. Choosing the appropriate saw blade ensures an efficient and safe cut. Different saws use different types of saw blades for making accurate cuts.

At first glance all hack saw blades may look alike but there actually is a difference. You can select the right blade for the job by checking the blade or part information booklet which will provide you with what kind of properties the blade can handle. From there youll be all set to choose the blades that best suit your woodworking needs and.

Heres the must-knows to help you choose the right blade as well as some key benefits to having a variety of blades at your disposal. You then turn the saw on its slowest setting and gently cut into the material lowering the saw into it until the base rests flat. On a hacksaw there are many types of blades these blades are different in many ways one of.

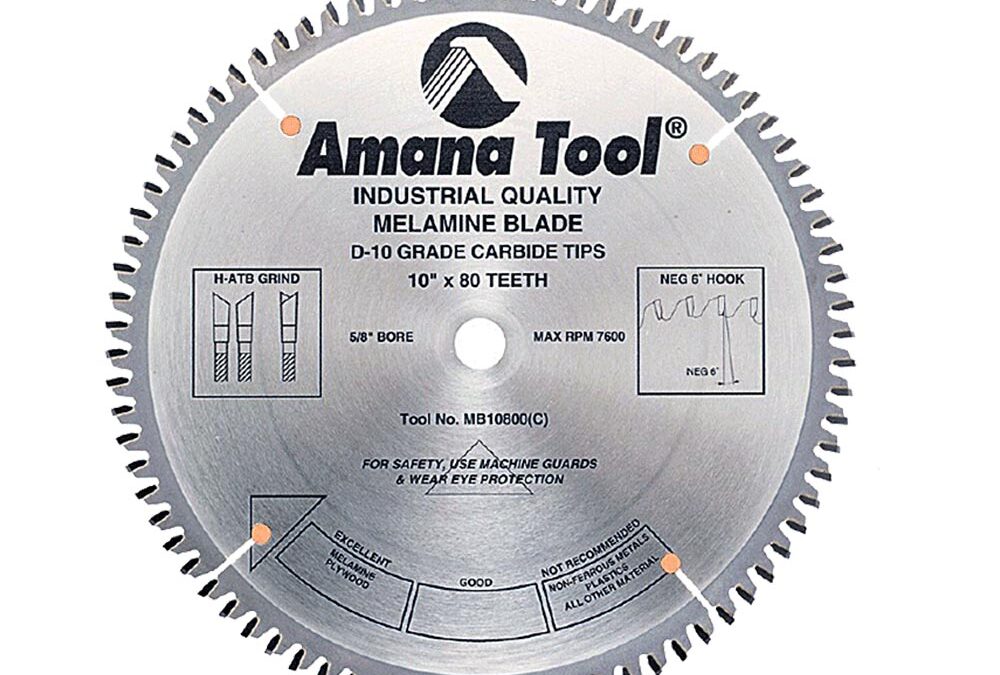

Generally blades have more teeth closer together the harder the material gets. Circular saw blades for plywood typically have more teeth to them and these can range from 40 teeth all the way up to. Soft wood blades have as few as 3 teeth per inch.

Cutting concrete will require a special blade usually a diamond blade of some sort and there are many different saws that can cut through concrete and the blades will differ slightly in appearance. Cutting through wood is obviously much different than glass or steel. You can use the same circular saw for multiple jobs by simply switching out the blade.

Also for different applications different types of saw blades are required to experience appropriate results. Different circular saws and materials require or perform best with blades optimized for that operation. A 14TPI blade is used for cutting large sizes aluminium and other soft.

If you want to cut nails or other metals you will want to select a blade with 32 teeth per inch. Most hacksaws are hand saws with a C-shaped walking frame that holds a blade under tension. Then you follow the line around.

The other way is to make a plunge cut. Order High Quality USA Welded Blades With Free Same Day Shipping On Orders Over 100. For some plastics a blade with 6.

There are general purpose blades that can handle different materials but if you know youre likely to only or mainly cut one type get a blade optimized for that. As with the hole-first cut make your plunge cut into the waste material. Blades are rated in TPI or Teeth Per Inch each of which is suited for cutting different materials and thicknesses.

This preview shows page 5 - 7 out of 7 pages. For instance the number of teeth per inch determines what type of material the blade can cut. Which blade you choose should depend on which metal you will be cutting.

Explain how to select saw blades for the different materials and how to set the saw blades for different operations. Any type of standard box tubing or normal cutting would be perfect for the IC bandsaw blade. Determine the blades number of teeth per inch.

Ad Same Day Shipping On All Bandsaw Blades Or Subscribe To Recieve Blades Every 2 or 4 Weeks. Number of Teeth How many teeth in a blade determines its cutting action. Choosing a Blade Set.

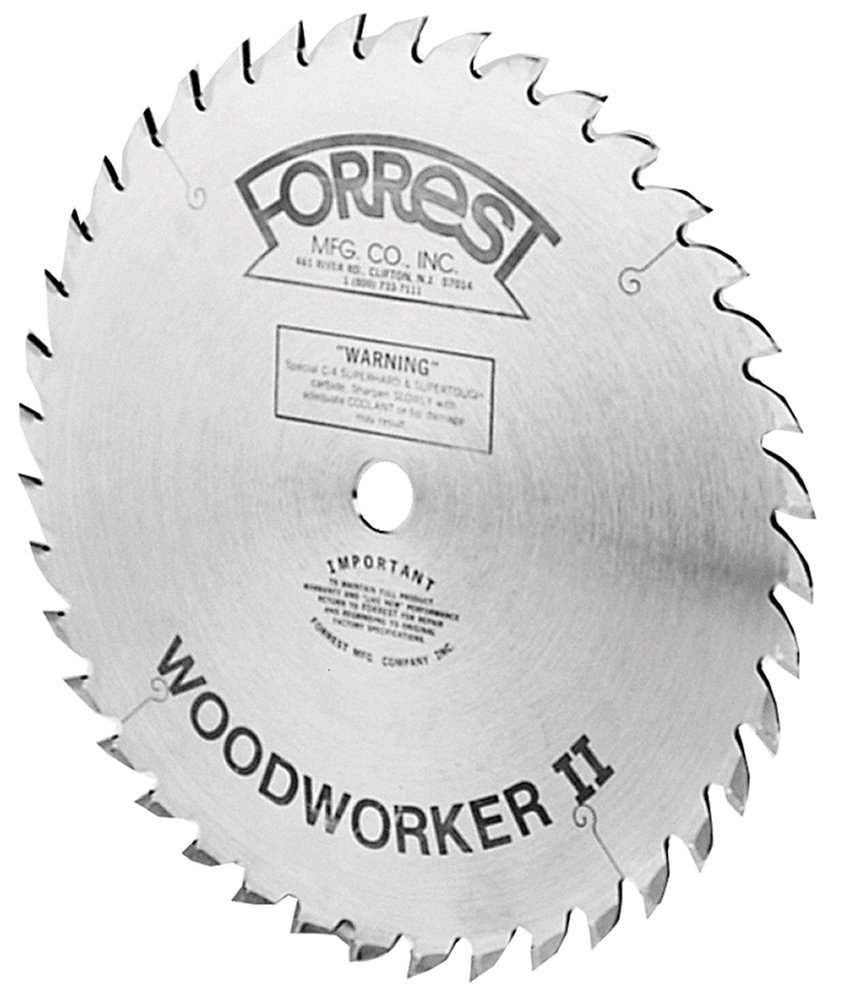

For heavy-duty cutting jobs like steel reinforcing rod or pipe an 18-teeth per inch blade would be the best choice. To put together the perfect saw blade collection you just need to know a little about what different types of saw blades do best and about what separates top-quality saw blades from the rest of the pack. The number of teeth per inch differentiates one blade from the next.

One of the most important parts of sawing metal is selecting the correct size blade for the job at hand. Jun 03 201921 -Explain how to select saw blades for different materials and how to set the saw blades for different operations such as cutting externally and internally On a hacksaw there are many types of blades these blades are different in many ways one of the ways is through the amount of teeth it has. Fortunately selecting the right hacksaw blade is simple if you follow a few guidelines.

You want to have anywhere from 3 to 24 teeth engaged in the material while youre cutting. A quality blade means a quality cut. Use the Right Hacksaw Blade.

How do you know which saw blades are best for which materials. Hardwood and laminate blades have 10 or more smaller teeth per inch. EAB produces quality.

Thats why EAB has over 140 unique blades to choose from each one designed to produce optimal results for the job at hand.

.jpg)

How Many Teeth Do I Need On My Saw Blade

Choosing The Right Saw Blade For Your Project

Woodworking Saw Blade Size Guide Circular Saws Miters Table Saws

.jpg)

How Many Teeth Do I Need On My Saw Blade

Essential Table Saw Blades Popular Woodworking

How To Pick The Right Miter Saw Blade Power Saw Expert

7 Tips For Choosing A Saw Blades Based On The Material You Cut

Table Saw Blade Selection Youtube

.jpg)

How Many Teeth Do I Need On My Saw Blade

Woodworking Saw Blade Size Guide Circular Saws Miters Table Saws

Woodworking Saw Blade Size Guide Circular Saws Miters Table Saws

Choosing A Saw Blade For Your Table Saw

Picking Circular Saw Blades Table Saw Miter Saw Youtube

Saw Blades Selection Guide Types Features Applications Engineering360

11 Circular Saw Blade Types You Need To Know

Comments

Post a Comment